Deltia.ai: Revolutionizing Assembly Line Productivity with AI

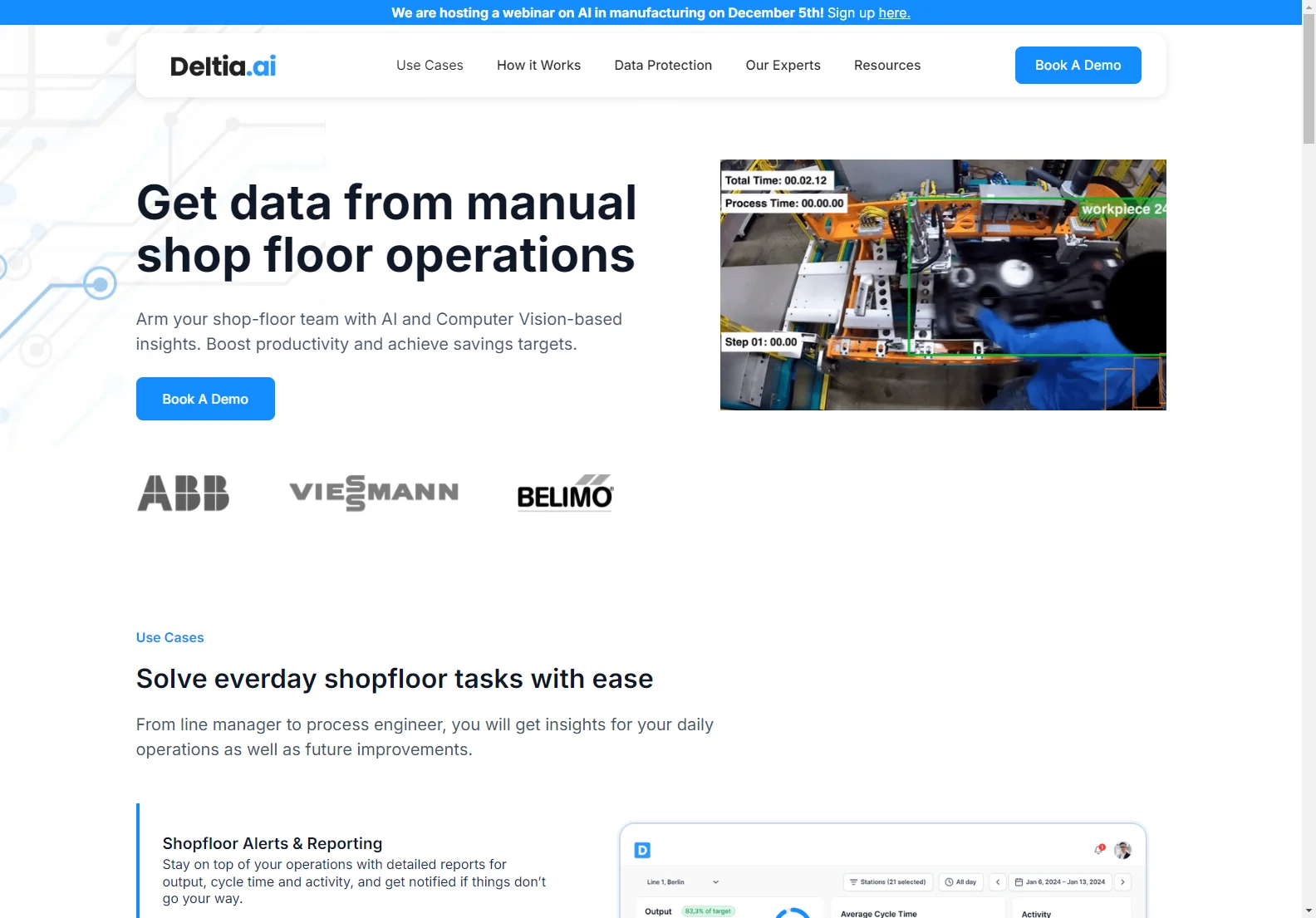

Deltia.ai leverages the power of AI and computer vision to dramatically boost efficiency and reduce costs in manufacturing assembly lines. This article explores how Deltia.ai achieves this, highlighting its key features, use cases, and the benefits it offers manufacturers.

Key Features

Deltia.ai offers a comprehensive suite of AI-powered tools designed to optimize assembly line operations:

- Shopfloor Alerts & Reporting: Receive real-time alerts and detailed reports on output, cycle time, and overall activity. Identify potential bottlenecks and address issues proactively.

- Improvement Measures: Deltia.ai analyzes workflows to pinpoint areas for improvement, prioritizing measures for maximum impact.

- Walking Routes Optimization: Analyze worker movement to identify inefficiencies and optimize walking routes, reducing wasted time and improving overall line flow.

Use Cases

Deltia.ai is applicable across various aspects of assembly line management:

- Line Managers: Gain real-time insights into line performance, enabling data-driven decision-making and immediate responses to issues.

- Process Engineers: Utilize detailed reports and analyses to identify long-term improvement opportunities and optimize processes for greater efficiency.

How it Works

Deltia.ai integrates seamlessly with existing shop floor operations, collecting data from various sources. Its AI algorithms then analyze this data to provide actionable insights and recommendations. The system is designed for ease of use and requires minimal training.

Data Protection

Deltia.ai prioritizes data security and privacy. Robust security measures are in place to protect sensitive data throughout the entire process.

Comparisons with Existing Solutions

Compared to traditional methods of assembly line monitoring and optimization, Deltia.ai offers a significant advantage through its AI-powered automation and real-time insights. This allows for faster identification of problems and more effective implementation of solutions, resulting in substantial cost savings and productivity gains. Unlike manual data collection and analysis, Deltia.ai provides continuous, automated monitoring, eliminating human error and improving accuracy.

Conclusion

Deltia.ai is a game-changer for manufacturers seeking to enhance productivity and reduce costs. Its AI-powered features provide unparalleled insights into assembly line operations, empowering businesses to make data-driven decisions and achieve significant improvements in efficiency and profitability.